SURFACE PREPARATION ENGINEERING PTE LTD

Products

Product Categories

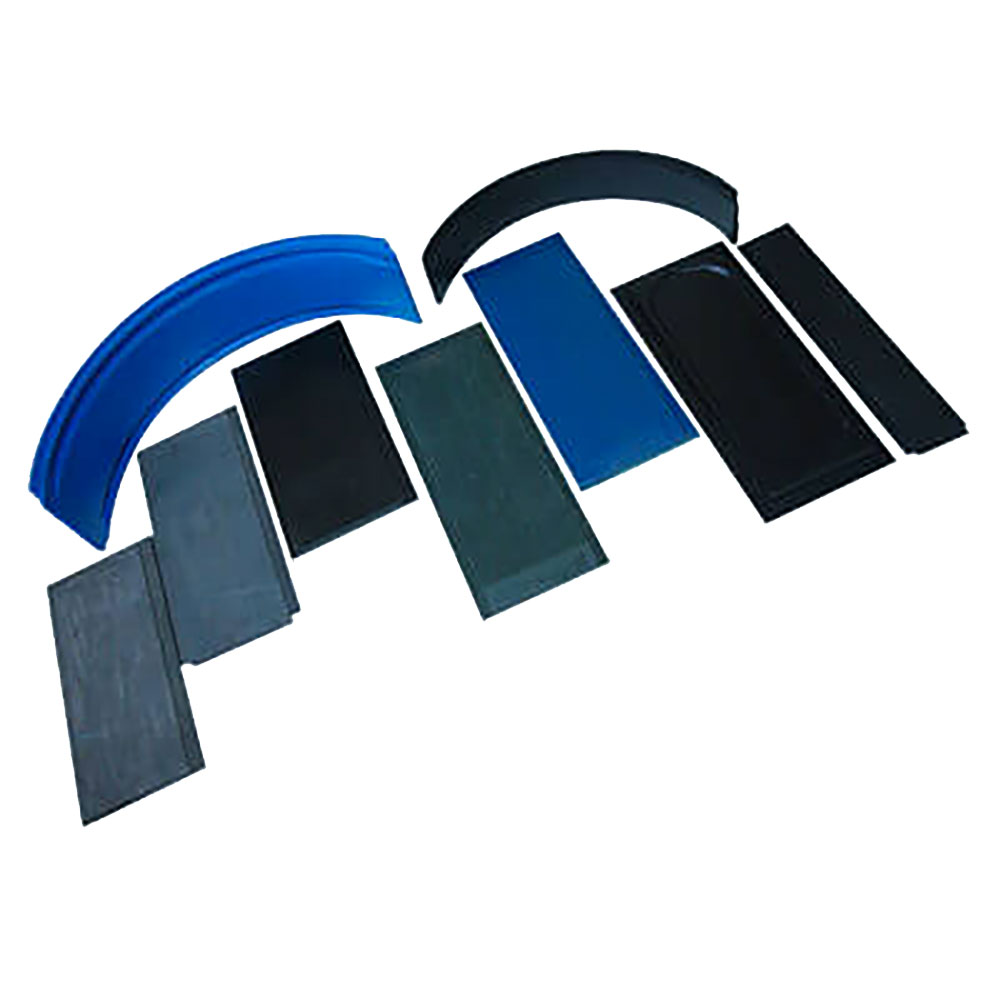

Wheel Liners

Wheel Liners, as essential blast wheel accessories and wear parts, are specialized components meticulously engineered to enhance the efficiency, longevity, and overall performance of blasting equipment. These liners play a pivotal role in abrasive blasting operations, particularly in machines equipped with rotating blast wheels. By offering a range of benefits, Wheel Liners contribute to achieving precise and consistent surface preparation results while safeguarding the integrity of the blasting wheel assembly.

Key Functions and Characteristics of Wheel Liners:

- Abrasive Media Guidance: Wheel Liners are strategically positioned within the blast wheel assembly to guide the trajectory and flow of abrasive media. By directing the abrasive particles towards the target surface, these liners optimize the abrasive projection process, resulting in controlled and uniform material removal.

- Impact and Wear Mitigation: During abrasive blasting, Wheel Liners act as a protective barrier between the abrasive media and the internal components of the blast wheel. They absorb a significant portion of the impact and wear generated by the abrasive particles, thereby minimizing wear and tear on critical parts and extending the overall lifespan of the equipment.

- Enhanced Efficiency: Properly designed Wheel Liners help streamline abrasive media flow, ensuring optimal utilization and minimizing wastage. This leads to improved blasting efficiency, reduced operational costs, and enhanced productivity.

- Surface Finish Consistency: Wheel Liners play a crucial role in achieving consistent and uniform surface finishes. By influencing the direction and intensity of abrasive projection, these liners contribute to a controlled and predictable surface preparation outcome.

- Maintenance Minimization: The wear-resistant nature of Wheel Liners reduces the frequency of maintenance and replacement of internal blast wheel components. This translates to decreased downtime and increased operational uptime.

- Customization and Adaptability: Wheel Liners are available in various designs and materials to accommodate different blasting requirements and abrasive media types. Their adaptability allows for tailored surface treatment solutions across diverse applications.

- Long-Term Cost Savings: By effectively protecting key blast wheel components, Wheel Liners contribute to reduced maintenance and replacement costs, optimizing the investment in blasting equipment over its lifespan.

Wheel Liners are integral components that optimize abrasive blasting operations by guiding abrasive media, protecting critical components, enhancing efficiency, and ensuring consistent and quality surface preparation. The design and functionality align with the commitment of Surface Preparation Engineering Pte. Ltd. to delivering high-quality industrial solutions for enhanced blasting performance and equipment durability.

QUICK LINKS

LOCATE US

28C Penjuru Close, #01-07

Singapore 609131

+65 6265 3488

enquiry@spe.com.sg

Surface Preparation Engineering Pte Ltd | 2022

Powered by: G Search - Singapore